Two-Stage Gear Reducer Design

Technical Datasheet

MECH-002Project Overview

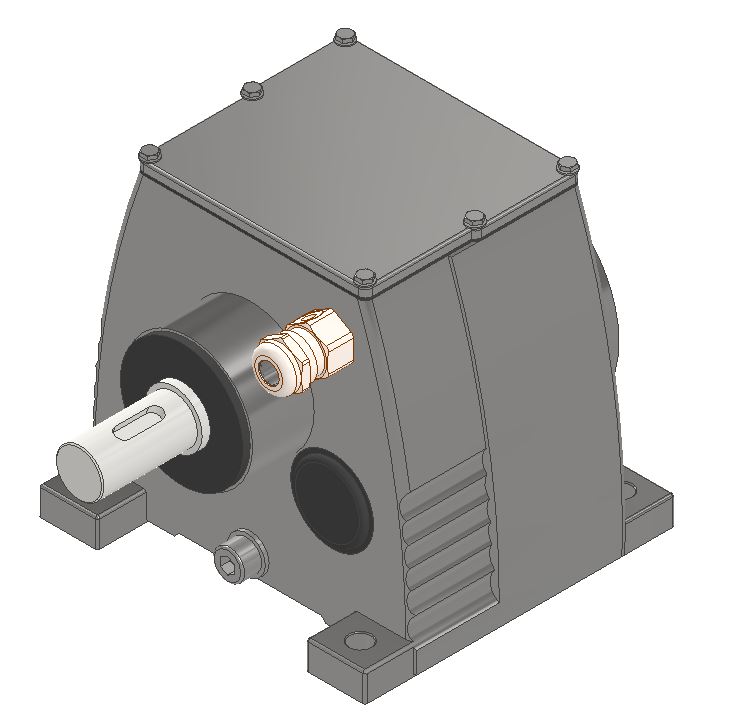

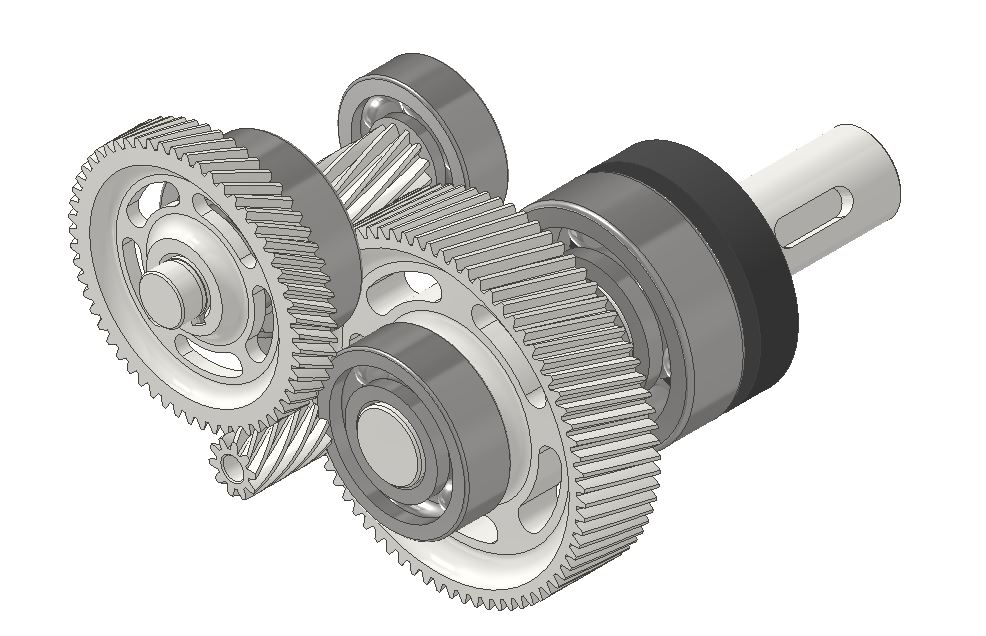

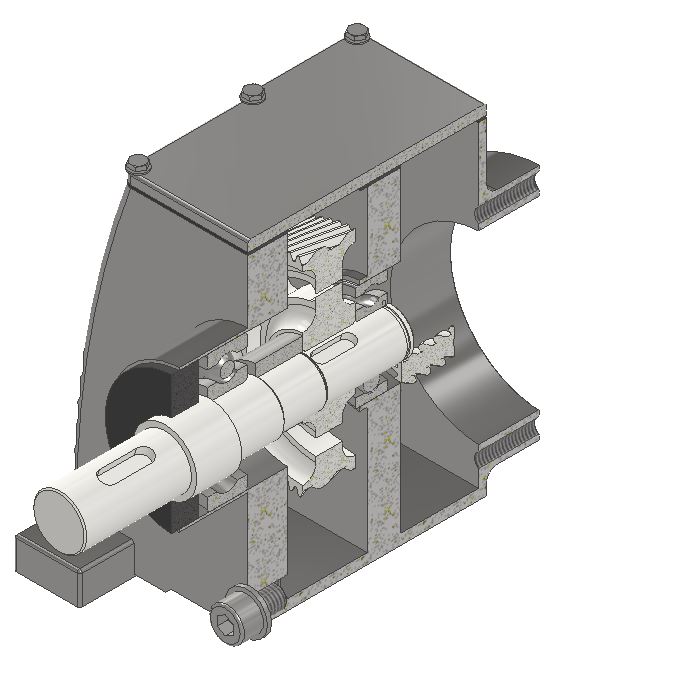

A complete analytical and graphical design of a two-stage cylindrical gear reducer with a single-piece housing. The project involved calculating multiple gear ratio variants, selecting the optimal transmission configuration, choosing a suitable electric motor based on output torque requirements, and generating manufacturing documentation.

The final design—consisting of shafts, gears, bearings, and reducer housing—was fully modeled as a 3D assembly in Autodesk Inventor, following technical standards for gear design and machine elements.

The final design—consisting of shafts, gears, bearings, and reducer housing—was fully modeled as a 3D assembly in Autodesk Inventor, following technical standards for gear design and machine elements.

Key Engineering Tasks

- Gear Geometry Calculation: Preliminary and detailed calculation of helical gear geometry and strength.

- Ratio Optimization: Multi-variant analysis to select the optimal transmission ratio based on torque and motor compatibility.

- Component Selection: Electric motor selection (SEW/Sever catalogs) and bearing life calculation.

- System Layout: Detailed arrangement of shafts, gears, bearings, and housing geometry.

- Manufacturing Documentation: Creation of workshop drawings for input shaft, output gear, and full assembly.

- 3D Modeling: Complete 3D assembly in Autodesk Inventor based on analytical results.

Tools & Technologies

Autodesk Inventor

Manual Gear Calculations (ISO)

Microsoft Excel

SEW & Sever Catalogs

Machine Elements Standards

3D Assembly Model

Project Gallery