Brake Disc Design, Stress Analysis & Technical Documentation

Technical Datasheet

MECH-006Project Overview

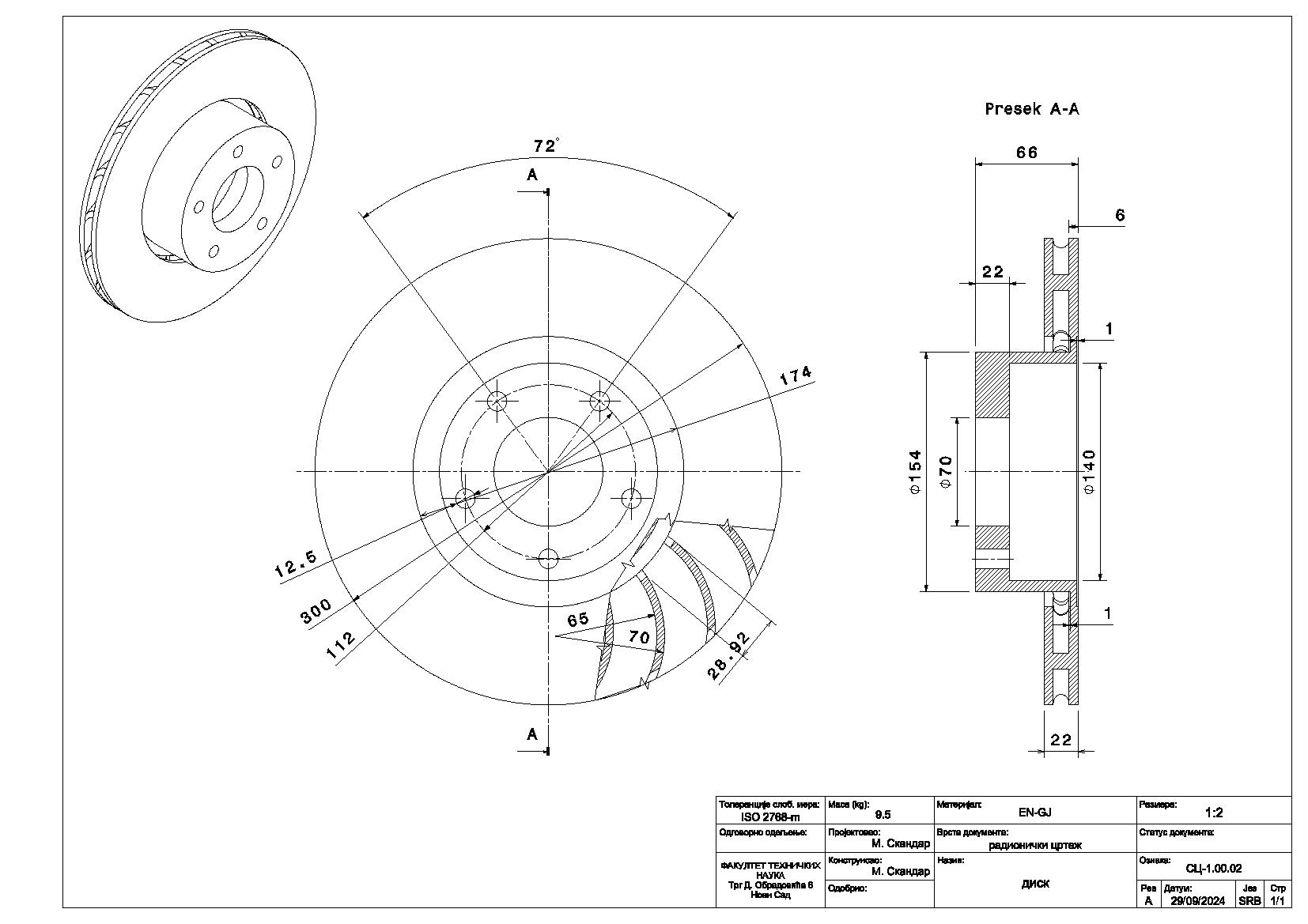

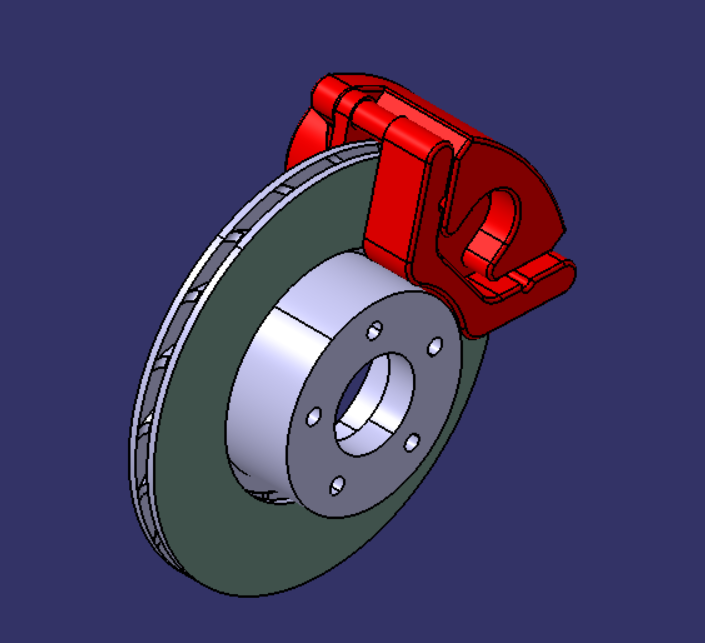

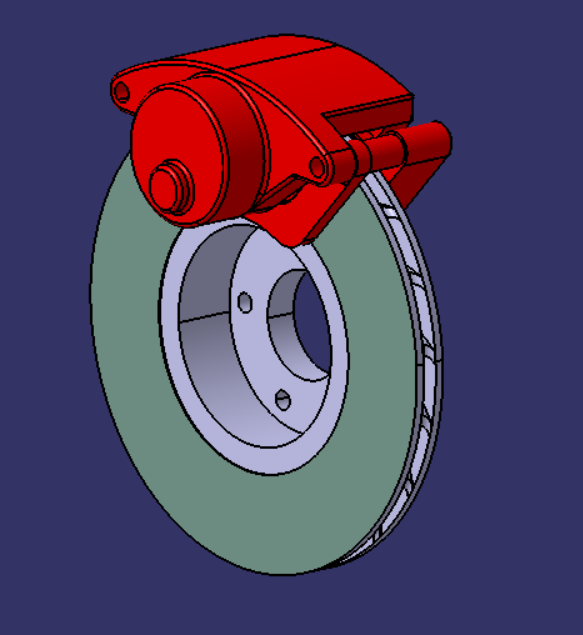

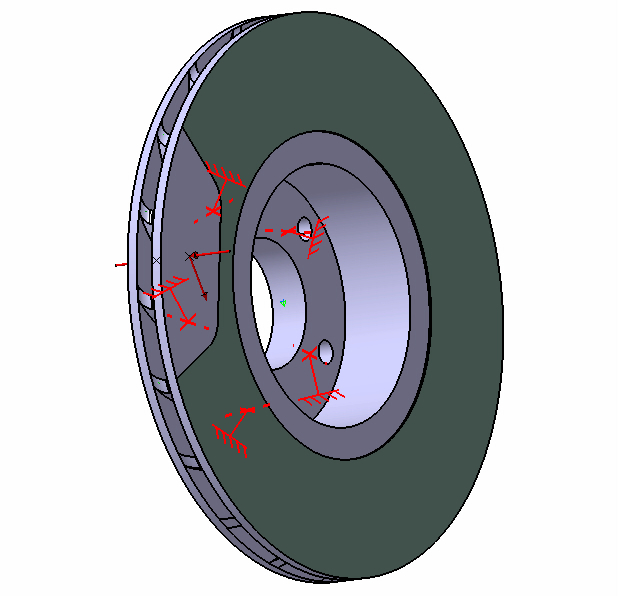

A complete mechanical engineering project focused on the design, modeling, and finite-element stress analysis of an automotive ventilated brake disc. This project combines CAD modeling (CATIA V5), mechanical load calculations, and FEM simulation workflow, demonstrating real-world skills used in mechanical design, automotive engineering, and CAE analysis.

The study includes 3D modeling of a ventilated brake disc, calculation of braking forces & torque, structural analysis using FEM, identification of critical stress regions, technical drawing creation, and comprehensive engineering documentation following industry standards.

The study includes 3D modeling of a ventilated brake disc, calculation of braking forces & torque, structural analysis using FEM, identification of critical stress regions, technical drawing creation, and comprehensive engineering documentation following industry standards.

Key Engineering Tasks

- CAD Modeling: Created parametric 3D ventilated brake disc with cooling ribs, mounting holes, and hub geometry in CATIA V5.

- Load Analysis: Calculated braking forces, normal loads (8400 N), tangential loads (3360 N), and torque distribution based on automotive parameters.

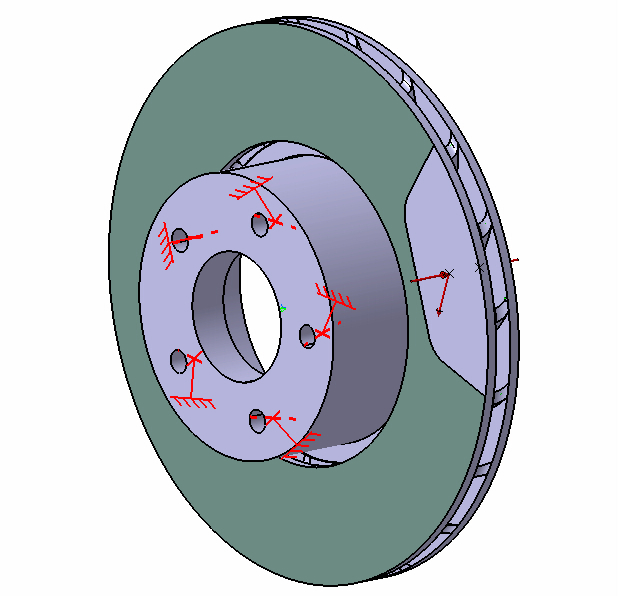

- FEM Setup: Applied boundary conditions, constrained bolt holes using virtual fixtures, and simulated pad pressure on both disc faces.

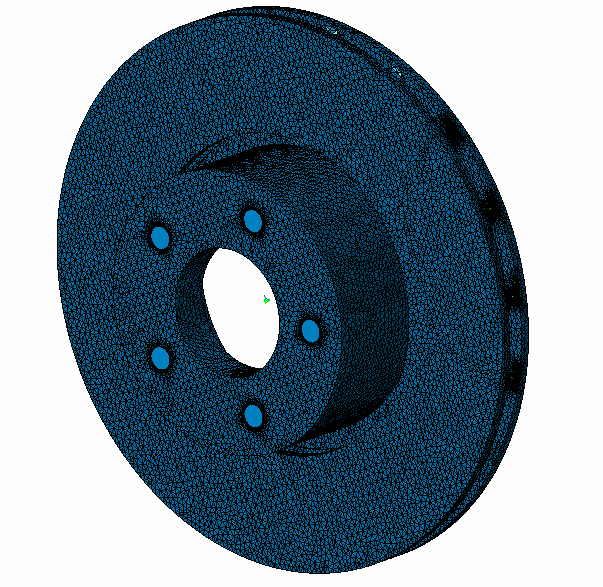

- Meshing Strategy: Used 3mm parabolic tetrahedral elements with 1mm local refinement around ribs and bolt holes for accurate stress concentration capture.

- Structural Analysis: Performed linear static FEM simulation to evaluate Von Mises stress distribution, principal stresses, and displacement field.

- Results Interpretation: Identified critical zones at rib edges and bolt hole boundaries, confirmed all stresses below yield strength (310 MPa).

- Technical Documentation: Generated 2D blueprints with ISO standard title blocks, section views (A-A, B-B), dimensions, and tolerancing.

- Engineering Report: Prepared comprehensive documentation including methodology, boundary conditions, FEA interpretation, and design validation.

Tools & Technologies

CATIA V5

FEM Simulation

Technical Drawing

Structural Analysis

3D Assembly Model

Project Gallery